When receiving and storing temperature-sensitive products, you must immediately record conditions using calibrated thermometers or data loggers to guarantee data accuracy. Continuously monitor storage temperatures, set alarms for deviations, and verify logs regularly to identify trends or issues. Proper documentation and prompt actions help maintain safety, quality, and compliance. By implementing these practices, you safeguard product integrity and strengthen your cold chain management — your next steps will reveal even more effective strategies.

Key Takeaways

- Record temperature conditions immediately upon product receipt using calibrated devices.

- Maintain detailed, timestamped logs of temperature data during storage and transfer.

- Regularly verify and calibrate measurement devices to ensure accurate temperature readings.

- Implement automated monitoring systems with alarms to detect and respond to temperature deviations promptly.

- Conduct routine reviews of temperature logs to identify trends, ensure compliance, and verify proper cold chain management.

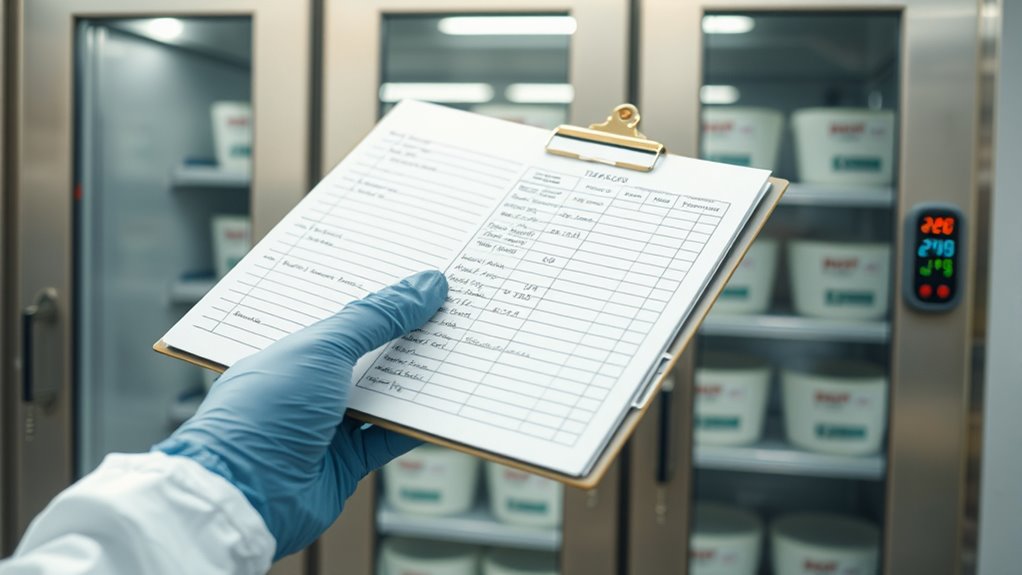

Have you ever wondered how organizations guarantee the safety and quality of their products through temperature monitoring? When it comes to receiving and storing temperature-sensitive items, maintaining cold chain integrity is essential. Cold chain integrity ensures that products like pharmaceuticals, food, or biologics stay within the required temperature ranges from the moment they’re shipped until they reach their final destination. To achieve this, you need to keep detailed temperature logs and verify them regularly. These logs serve as a record of temperature conditions during transport and storage, helping you identify any deviations that could compromise product quality or safety. Accurate and consistent documentation is critical, especially when audits or regulatory inspections occur, because compliance documentation proves your organization’s adherence to industry standards and legal requirements.

When you receive temperature-sensitive goods, it’s vital to immediately record the conditions upon arrival. Use calibrated thermometers and data loggers to capture real-time temperature data. These devices should be checked regularly for accuracy, and their readings documented meticulously. If you notice temperature excursions—whether too high or too low—promptly investigate the cause and take corrective actions. Recording these incidents clearly and comprehensively is part of maintaining compliance documentation, which demonstrates your organization’s commitment to quality assurance standards. Properly maintained logs not only support ongoing product safety but also help you trace any issues back to their source, whether during transit or storage. Incorporating regular audits of your temperature logs can further improve your cold chain management by identifying areas for improvement.

For storage, continuous temperature monitoring is non-negotiable. Automated systems that generate electronic temperature logs can simplify this process, ensuring accuracy and ease of access for review. You should set alarms to alert staff immediately if temperatures drift outside set parameters, enabling quick responses to prevent product spoilage or contamination. Every temperature check should be timestamped and signed off by responsible personnel, reinforcing accountability and traceability. By doing so, you build a reliable record that supports compliance documentation and reassures stakeholders that your organization follows best practices for cold chain management.

Ultimately, verifying temperature logs isn’t just about record-keeping; it’s about actively safeguarding product integrity. Regularly reviewing logs helps you spot trends, identify potential risks, and improve procedures. When maintained diligently, these logs serve as proof of compliance, demonstrating that you’ve taken every necessary step to uphold product safety standards. In doing so, you protect your organization from regulatory penalties, product recalls, and damage to reputation. Keeping detailed, accurate temperature logs and verifying them consistently is a straightforward yet crucial part of managing a robust cold chain, ensuring that every product reaches its destination in prime condition.

Frequently Asked Questions

How Often Should Temperature Logs Be Reviewed for Accuracy?

You should review your temperature logs daily to verify accuracy, especially when using digital logging systems. Regular daily reviews help catch any discrepancies early. If you rely on manual verification, consider checking logs at least once per shift or daily. Consistent reviews maintain compliance and ensure your storage conditions stay within safe temperature ranges. Staying proactive with daily verification helps prevent issues before they escalate, keeping your products safe and compliant.

What Are Common Mistakes When Maintaining Temperature Logs?

It’s funny how easy it is to overlook details in temperature logs, yet small mistakes can cause big issues. You might think inconsistent logging or data entry errors are minor, but they can lead to incorrect temperature records. Forgetting to record data promptly or using inconsistent formats makes tracking accuracy difficult. Always double-check entries and follow a consistent logging schedule to avoid these common mistakes, ensuring your storage stays within safe limits.

How Long Should Temperature Records Be Retained?

You should retain temperature records for at least one year, following your organization’s record retention policies. This guarantees compliance with data management best practices and regulatory requirements. Regularly review and securely store these logs to facilitate quick access during audits or investigations. Proper record retention helps maintain data integrity, supports quality assurance, and demonstrates your commitment to food safety and regulatory compliance.

What Tools Are Best for Recording Temperature Data?

Imagine a sleek digital thermometer in your hand, instantly capturing precise temperature readings. You can also rely on data loggers, which continuously record data like tiny sentinels guarding your storage area. These tools are your best options for recording temperature data, offering accuracy and ease of use. With digital thermometers and data loggers, you’ll keep detailed, reliable records effortlessly, ensuring your storage conditions stay within safe limits at all times.

How Do Temperature Deviations Impact Product Safety?

Temperature fluctuations can seriously impact product safety by creating contamination risks and compromising quality. When temperatures deviate from the recommended range, bacteria and other pathogens can grow, increasing the likelihood of spoilage or illness. You need to monitor and verify temperature data regularly to prevent these issues. Maintaining consistent temperatures guarantees your products stay safe, fresh, and compliant, reducing the chance of contamination and safeguarding consumer health.

Conclusion

By diligently maintaining temperature logs and verification, you guarantee your storage practices stay in harmonious balance. Regular checks act like gentle guardians, quietly safeguarding the integrity of your products. When you stay attentive and proactive, you create a smooth, reliable environment that nurtures quality and safety. Remember, a little consistent effort now keeps potential issues softly at bay, allowing your operations to flourish gracefully and without interruption.