Choosing the wrong meat slicer blade size can make slicing frustrating and inefficient. Small blades may struggle with dense meats, leading to uneven cuts and more effort, while large blades can be unwieldy for delicate slices and slow you down. Using an incompatible size risks safety issues and poor results. To avoid these problems, it’s essential to select the right blade for your needs. Keep exploring to discover how to choose the perfect blade size for your tasks.

Key Takeaways

- Choosing the wrong blade size causes uneven slices, increasing effort and frustration during meat slicing tasks.

- Smaller blades struggle with dense meats, forcing multiple passes and slowing down workflow.

- Larger blades can be unwieldy for delicate, thin slices, reducing precision and increasing safety risks.

- Inappropriate blade sizes lead to increased food waste due to inconsistent cuts.

- Using the wrong size compromises safety and can damage the slicer or blade prematurely.

Choosing the right meat slicer blade size is essential for achieving precise cuts and efficient workflow in your kitchen or deli. When you select the proper blade, you ensure that your slices are uniform, saving you time and reducing waste. Conversely, using a blade that’s too small or too large for your needs can turn your workday into a frustrating battle. So, it’s crucial to understand how blade size impacts your slicing tasks and how to maintain safety and performance.

Choosing the right blade size ensures precise cuts, efficiency, and safety in your slicing tasks.

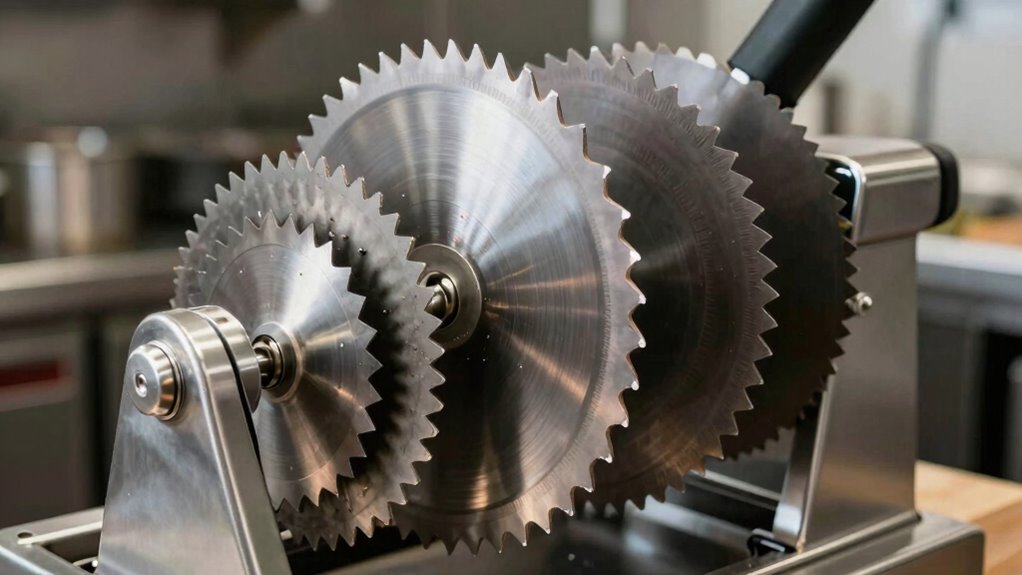

First, consider the types of meats and foods you typically process. A smaller blade, around 7 to 9 inches, works well for delicate, thin slices like cold cuts or cheese, offering precision and control. Larger blades, 10 to 14 inches or more, are better suited for thicker cuts or larger quantities of meat, providing the power and speed needed for heavy-duty slicing. Choosing the wrong size can make your job harder; a small blade may struggle with dense meats, requiring multiple passes, while a large blade might be cumbersome for small, delicate slices, increasing the risk of uneven cuts.

Safety precautions are vital when working with different blade sizes. Always wear cut-resistant gloves when handling blades, especially when cleaning or changing them, to prevent injuries. Ensure the slicer is unplugged before performing maintenance or blade adjustments. Use the proper tools for blade removal and installation, following your slicer’s manufacturer instructions carefully. Larger blades can pose a higher risk due to their weight and sharpness, so handle them with extra caution. Keep your workspace clean and free of obstructions to avoid accidents, and never bypass safety features or attempt to force a blade into place.

Maintenance tips also play a critical role in keeping your slicer functioning correctly. Regularly inspect your blades for dullness, chips, or corrosion, which can compromise safety and quality. Clean blades thoroughly after each use with warm, soapy water, avoiding harsh abrasives that could damage the edge. Sharpen blades as recommended—dull blades not only produce uneven slices but also increase the risk of slips and injuries. Proper lubrication of moving parts ensures smooth operation and prevents overheating. Storing blades safely in designated containers or sheathes minimizes accidental cuts and prolongs their lifespan. Additionally, understanding blade size compatibility and selecting the appropriate tools can significantly enhance your safety and efficiency.

Frequently Asked Questions

Can I Use a Larger Blade on a Smaller Meat Slicer?

Using a larger blade on a smaller meat slicer isn’t recommended because of blade compatibility issues. It can interfere with slicer maintenance, making cleaning and safety checks harder. Plus, a larger blade might not fit securely, risking damage or accidents. Always choose the right-sized blade for your slicer to ensure smooth operation, safety, and easy maintenance. Stick to the manufacturer’s specifications to avoid daily frustrations and keep your slicer in top shape.

How Often Should I Replace My Meat Slicer Blade?

You should replace your meat slicer blade at least every 6 to 12 months, depending on use. Neglecting blade maintenance can turn slicing into a chore, not a pleasure, and incompatible blades can ruin your slicer’s performance. Regular inspections ensure slicer compatibility and prevent dullness or damage. If your slices start to look uneven or require extra effort, it’s time to swap that blade before it sabotages your kitchen adventures.

Are There Safety Concerns With Different Blade Sizes?

Yes, there are safety concerns with different blade sizes. A larger blade can be harder to control, increasing the risk of accidents, especially if it’s made from low-quality blade material. Always wear appropriate safety gear, like cut-resistant gloves, and handle blades carefully. Using the correct blade size for your slicer helps prevent injuries, ensuring safer operation and smoother slicing. Proper maintenance and cautious handling are key to safety.

Do Blade Sizes Affect the Slicing Speed?

Blade sizes are like gears in a machine—larger blades often mean faster slicing, but only if you keep up with proper blade maintenance. A correctly sized blade enhances slicing precision and speed, helping you work efficiently without sacrificing quality. When your blade is well-maintained, it glides smoothly, allowing you to process more slices with less effort. Choose the right size and keep it sharp for ideal speed and accuracy.

Can I Sharpen Blades of Any Size?

You can sharpen blades of any size, but it’s easier with the right sharpening tools. Use a sharpening stone or honing steel suited to your blade material, whether stainless steel or carbon steel. Larger blades may need more effort and specific tools, while smaller ones are quicker to sharpen. Always follow the manufacturer’s instructions for your blade size and material to guarantee a safe, effective sharpen.

Conclusion

Choosing the right meat slicer blade size isn’t just about convenience; it’s about consistency, safety, and efficiency. When you pick the right size, you gain precision, reduce frustration, and enjoy smoother slicing. When you understand your needs, match your blade, and prioritize quality, you set yourself up for success. Because the right blade isn’t just a tool—it’s the foundation of every perfect slice, every time. Make the right choice, and slicing becomes second nature.