Choosing the best finish for your restaurant tables is essential for durability and appeal. Opt for a polyurethane finish or 2K urethane; they resist heat and spills while looking great. Conversion varnish is another excellent choice, especially for high-traffic areas. Regular maintenance is key, so inspect and clean your tables frequently to prevent wear. Reapply your chosen finish every few years to keep it looking fresh. Guarantee you consider your restaurant's unique needs and environment when selecting a finish. Stick around, and you'll discover more tips on keeping your tables looking their best.

Key Takeaways

- Choose finishes like 2K urethane or catalyzed conversion varnish for superior heat and spill resistance in high-traffic restaurant environments.

- Regular inspections and immediate spot repairs are crucial for maintaining the appearance and longevity of restaurant table finishes.

- Maintain optimal temperature and humidity during application to ensure proper curing and enhance finish durability.

- Schedule reapplication of high-quality finishes every 3-5 years to protect against wear and tear from constant use.

- Clean tables with warm water and soft cloths, avoiding harsh chemicals to preserve finish integrity and appearance.

Types of Finishes

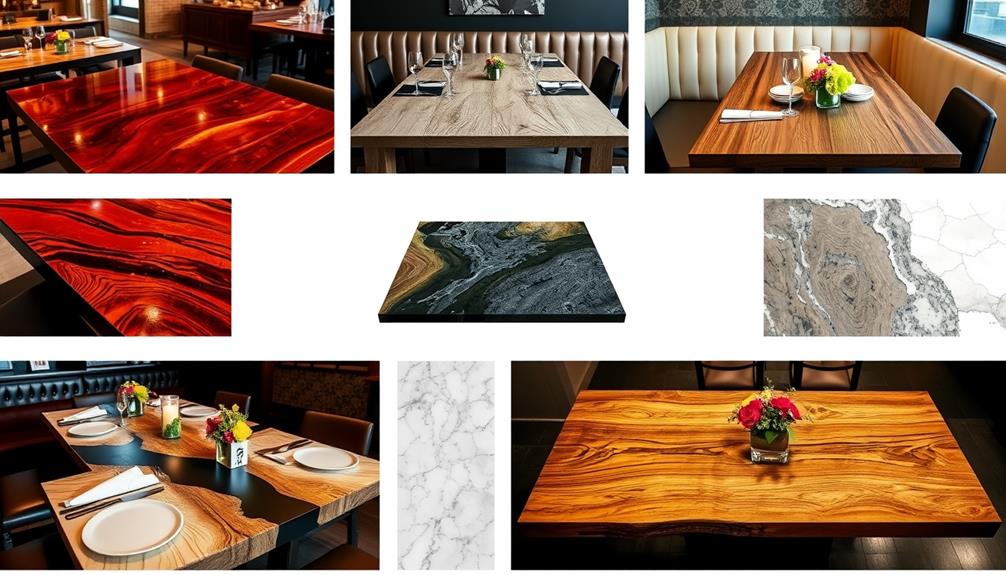

When choosing the best finish for restaurant tables, it's crucial to understand the various types available. One popular option is varnish, particularly traditional oil-based varnish, which offers exceptional durability and resistance to wear, making it ideal for surfaces that require long-term maintenance.

This durability is similar to the importance of maintaining a good credit score, which influences loan terms and overall financial health.

Another great option is a polyurethane finish. It's highly chemical-resistant and waterproof, ideal for tables that often face spills and heavy use. You can find polyurethane finishes in both oil and acrylic bases, giving you flexibility based on your needs.

If you're looking for something even more robust, consider conversion varnish. This finish is often preferred due to its superior durability and chemical resistance. It forms a tough, cross-linked surface that can withstand the rigors of high-traffic dining environments.

Lastly, oil/wax blends can be appealing for their aesthetic qualities and ease of maintenance. They allow for touch-ups and repairs without the need for complete refinishing, making them practical for busy restaurant settings.

Ultimately, choosing the right finish will depend on your specific needs and the dining experience you aim to create.

Durability Challenges

When choosing a finish for your restaurant tables, you need to take into account durability challenges like heat resistance and spill protection.

Selecting a sturdy finish is essential because it must withstand the rigors of constant use while also being easy to clean and maintain to guarantee longevity.

Hot plates and liquid spills can quickly ruin sensitive surfaces, so it's important to choose materials that can handle such challenges effectively.

You'll also want to manage wear and tear from constant use to keep your tables looking their best, as energy-saving features can be applied metaphorically to the choice of finishes that help reduce maintenance efforts.

Heat Resistance Requirements

In the bustling environment of a restaurant, heat resistance is a significant consideration for table finishes. Your tables endure constant exposure to hot plates and beverages, which can damage less resilient finishes.

To guarantee longevity and durability, you should opt for high-performance finishes like catalyzed conversion varnish or 2K urethanes. These options offer excellent heat resistance, making them ideal for high-use environments, similar to how high refresh rates enhance gaming experiences.

While water-based finishes are eco-friendly, they often struggle to withstand heat, leading to unpleasant issues like cork mats sticking to surfaces when heated.

Consequently, it's vital to prioritize durable finishes that can handle the rigors of a restaurant's daily operation. Frequent spills from hot food and beverages can also compromise the integrity of your table finishes, so applying heat-resistant coatings is a smart move.

Don't forget the importance of proper curing time, too. Allowing finishes to cure for at least four weeks will help achieve peak heat resistance, guaranteeing your tables remain looking great and functional.

Spill Protection Strategies

Steering through the challenges of spills in a restaurant setting requires strategic thinking about table finishes. You can't afford to overlook the importance of durable finishes that stand up to high traffic and frequent spills.

Here are three vital spill protection strategies you should consider:

1. Choose the Right Finish: Opt for 2K urethane or catalyzed conversion varnish, as these provide superior resistance to heat, moisture, and chemicals.

Regular water-based finishes often fall short, leading to issues like cork backing sticking and unsightly cold water stains.

2. Allow Proper Curing Time: Don't rush the process. Allow approximately four weeks for finishes to cure fully.

This guarantees they reach maximum durability, protecting against scratches and dents in busy dining areas.

3. Implement Regular Maintenance: Regular upkeep is essential.

Scuff sanding and reapplying finishes will help preserve both the aesthetic and functional integrity of your tables.

This proactive approach minimizes the need for future refinishing while providing long-lasting protection.

Wear and Tear Management

Restaurant tables endure constant wear and tear from high traffic, hot dishes, and accidental spills, making durability an essential factor in your selection process.

Choosing the right finish is critical; high-quality options like 2K urethane and catalyzed conversion varnish are ideal for high-use environments due to their resistance to heat and moisture. These finishes not only enhance the table's appearance but also contribute considerably to its durability.

Regular maintenance is essential for prolonging the life of your tables. Scuff sanding and reapplying the finish can keep surfaces looking fresh and can extend their longevity.

Cross-linked finishes, in particular, can last up to 10 years with proper care, reducing the need for frequent refinishing.

Recommended Products

When choosing the best finish for your restaurant tables, it's essential to take into consideration products that can withstand the demands of a high-traffic environment. With the constant bustling of customers and possible spillages, a durable finish on table surfaces is a must. Look for finishes that are scratch-resistant, easy to clean, and have a high resistance to heat and moisture. These features will ensure that your restaurant tables not only look great but also remain in top condition for years to come, making your establishment one of the top dinner spots for groups.

Here are three top recommendations to reflect on:

- 2K Urethane: This finish offers superior durability and resistance to heat and spills, making it perfect for busy dining areas. Its hard surface protects against scratches and stains, ensuring your tables look great for longer.

- Oil-based Varnish (like Min-Wax Fast Dry): This option strikes a balance between durability and ease of application. It's versatile enough for various table styles and provides a solid protective layer against everyday wear.

- Rubio Monocoat: Although it comes with a higher price tag, this product is worth the investment. Known for its exceptional durability and aesthetic appeal, Rubio Monocoat is easy to apply and ideal for high-use surfaces.

With these products, you can enhance the longevity and appearance of your restaurant tables, ensuring they can handle the hustle and bustle of your dining environment.

Choose wisely, and your tables will thank you!

Application Techniques

Achieving a flawless finish on your restaurant tables requires careful attention to application techniques. Start by using a sprayer for even coverage, but don't forget to wear proper personal protective equipment (PPE) for safety.

When working with oil-based finishes, stir the product thoroughly to eliminate bubbles and avoid over-brushing, which can ruin the finish. Aim for multiple thin coats—typically 4 to 6—to maximize durability, especially on high-use surfaces.

Allow 4-6 hours of drying time between coats for the best results. To enhance adhesion and achieve a smoother final finish, scuff sand between each coat using fine-grit sandpaper.

It's also critical to test your application method and finish under expected usage conditions. This step helps prevent future issues and guarantees long-lasting results, making your tables not just visually appealing but also easy to repair if needed.

Maintenance Best Practices

Maintaining the finish on your restaurant tables is essential for guaranteeing their longevity and durability, especially in a high-traffic environment.

Regular maintenance helps prevent wear and tear, keeping your tables looking great and functional. Here are some best practices to follow:

- Regular Inspections: Check your tables for scratches and dents frequently. Spot repair any damage immediately to prevent further issues and prolong the life of the finish.

- Proper Cleaning: Use warm water and soft cloths for cleaning. Avoid harsh chemicals that can degrade the protective layer and compromise the finish's durability.

- Reapply Finish: Every 3-5 years, consider scuff sanding and reapplying a high-quality finish, like 2K urethane or catalyzed conversion varnish. This guarantees your tables maintain their resistance to heat and spills, reducing future maintenance needs.

Also, remember to allow sufficient curing time—around 4 weeks—after finishing to guarantee the protective layer fully hardens.

Following these maintenance best practices will help you keep your restaurant tables in top shape for years to come.

Environmental Considerations

When you're finishing restaurant tables, local temperature and humidity can really affect how your finish applies and dries.

It's important to adjust your techniques based on these conditions to achieve the best results.

Keeping an eye on these environmental factors will help guarantee a quality finish that lasts.

Temperature Effects on Application

Temperature plays an essential role in the application of finishes on restaurant tables. The right temperature can markedly influence both drying time and finish quality. Here are three key points to keep in mind:

- Optimal Temperature Range: Aim to apply finishes between 65°F and 85°F. This range promotes ideal curing and bonding characteristics, guaranteeing a durable finish.

- Impact of Warm Conditions: Warmer temperatures speed up the drying process, allowing you to move on to the next steps more quickly.

- Challenges of Cooler Temperatures: In cooler conditions, drying time can extend, potentially compromising the finish's integrity and adhesion.

It's also vital to monitor humidity levels, as high humidity can lead to slow curing and adhesion issues.

If you're working in low humidity, consider using retarder solvents to maintain a workable finish consistency. Just remember that this might increase VOC emissions.

Humidity and Drying Times

Humidity plays an essential role in the drying times of finishes applied to restaurant tables. When humidity levels are high, you might notice that drying periods can stretch longer than expected, impacting the finish's curing process. This slow drying can lead to issues like brush marks or an uneven finish, which you definitely want to avoid in a professional setting.

During those low humidity months, especially in winter, consider using retarder solvents to help slow down the drying process. This can provide more time for you to achieve an even application. However, it's worth mentioning that many finish suppliers can't offer specific recommendations on these solvents, so understanding your local environmental conditions is fundamental.

Proper ventilation is also critical in humid environments. It not only promotes faster drying but helps mitigate health risks associated with solvent use.

Frequently Asked Questions

What Is the Best Finish for Restaurant Table Tops?

When choosing a finish, consider durability and ease of maintenance. You'll want something that withstands heat and spills, like a high-quality oil-based varnish, ensuring your tables look great and last longer in busy settings.

What Are Restaurant Tables Coated With?

Did you know that 70% of diners prefer restaurants with well-maintained tables? Restaurant tables are often coated with durable finishes like oil-based varnish, water-based polyurethane, or lacquer to withstand high traffic and frequent spills.

What Is the Most Durable Finish for a Kitchen Table?

For a kitchen table, you'll want a durable finish like catalyzed varnish or high-quality oil-based varnish. These options resist heat and spills, ensuring your table stays beautiful and functional for years with proper maintenance.

What Is the Best Coating for Bar Tables?

Bar tables benefit best from a brilliant blend of bold coatings. You'll find catalyzed conversion varnish and 2K urethane excel in endurance, while eco-friendly finishes guarantee safety and sustainability. Regular maintenance keeps them looking new!

Conclusion

To sum up, selecting the ideal finish for your restaurant tables is more than just an aesthetic choice; it's about ensuring longevity and maintaining an inviting atmosphere. By considering the durability challenges and employing the right application techniques, you can create a warm, welcoming environment for your guests. With proper maintenance and a mindful approach to environmental impacts, your tables will not only endure but also reflect the charm and character of your establishment.