A HACCP plan guides you step-by-step to identify and control hazards at each stage of food production, from raw materials to packaging. You’ll analyze biological, chemical, and physical risks, and determine critical control points where hazards can be prevented or reduced. Implementing preventive measures guarantees food safety proactively rather than reactively. By following this structured approach, you’ll strengthen your food safety system and meet regulatory standards—there’s more to discover to make your plan effective.

Key Takeaways

- Outline each step of the HACCP process, from hazard analysis to verification.

- Identify potential biological, chemical, and physical hazards at each production stage.

- Determine critical control points (CCPs) where hazards can be effectively managed.

- Develop and implement preventive measures and monitoring procedures for each CCP.

- Regularly review and verify the HACCP plan to ensure ongoing food safety compliance.

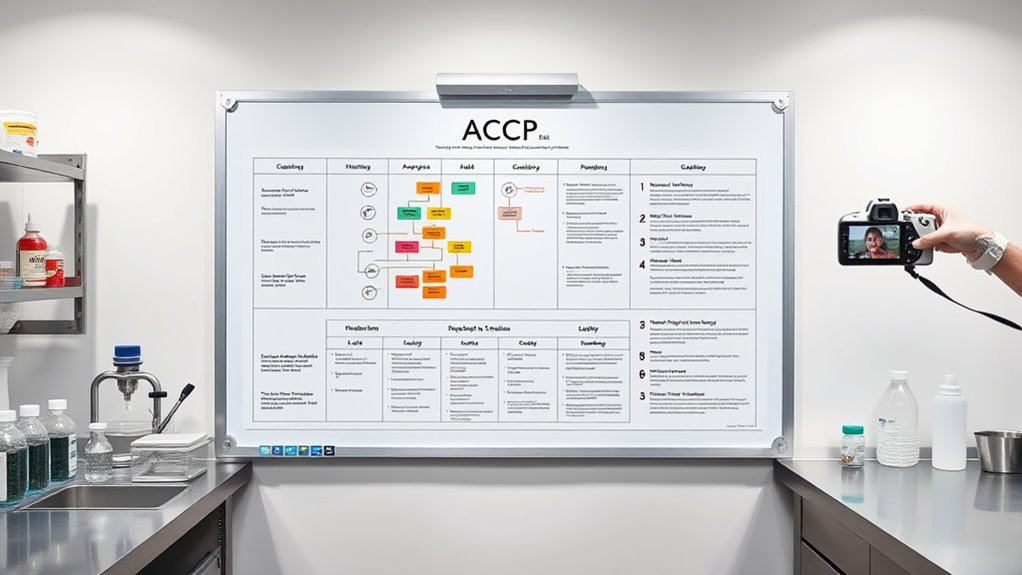

Have you ever wondered how food producers guarantee their products are safe from contamination? The answer lies in a structured approach called the HACCP plan. This plan focuses on food safety by systematically identifying and controlling hazards throughout the production process. One of the first steps in creating an effective HACCP plan is conducting a thorough hazard analysis. This involves examining every stage of your operation—from raw material receipt to final packaging—and pinpointing potential hazards that could compromise food safety. These hazards might be biological, such as bacteria or viruses; chemical, like cleaning agents or pesticides; or physical, including foreign objects like metal shards or plastic pieces. By understanding where and how these hazards could occur, you set the foundation for effective prevention.

During hazard analysis, you’re essentially mapping out all possible risks. You’ll need to ask yourself questions like: what are the critical points where contamination could happen? Which ingredients or steps pose the highest risk? Once you identify these hazards, you can prioritize them based on their severity and likelihood. This step is vital because it helps you focus your resources on controlling the most significant risks first. It also guides you in designing preventive measures that are both practical and effective. For example, if raw poultry is a hazard for Salmonella contamination, you might implement specific temperature controls or sanitation procedures at the processing stage.

Food safety isn’t just about reacting to problems; it’s about preventing them from happening in the first place. That’s why hazard analysis is a cornerstone of the HACCP plan. It provides you with a clear picture of where vulnerabilities exist and what actions are necessary to eliminate or reduce risks. By carefully analyzing hazards, you develop a proactive approach rather than relying solely on end-product testing, which can sometimes miss hazards. This systematic evaluation ensures every critical control point is identified, so you can put appropriate measures in place to monitor and control potential hazards effectively.

Additionally, integrating somatic therapy techniques can improve overall well-being by reducing stress and supporting emotional resilience, which can positively influence safety-focused decision-making in food production.

Frequently Asked Questions

How Often Should a HACCP Plan Be Reviewed and Updated?

You should review your HACCP plan regularly, at least annually, to make certain it remains effective. However, your update frequency may need to be higher if there are changes in your process, ingredients, or regulations. Conduct a plan review whenever there’s a new hazard, equipment change, or after an incident. Staying proactive helps you maintain food safety and compliance, so make plan review and updates a routine part of your operations.

What Are Common Challenges in Implementing a HACCP Plan?

You might face challenges like ensuring employee compliance, as staff may overlook critical procedures. Additionally, resource allocation can be tough, especially when balancing costs and time needed for proper implementation. To overcome these issues, you should provide thorough training and clear communication, emphasizing the importance of HACCP. Regular monitoring and management support help maintain adherence, making your plan more effective and sustainable in the long run.

Who Should Be Responsible for HACCP Plan Documentation?

You’re responsible for HACCP plan documentation, guaranteeing it’s accurate and accessible. As the key keeper, you must maintain meticulous records of all procedures, monitoring, and corrective actions. Your role involves managing employee responsibility by training staff to follow protocols precisely. By prioritizing proper documentation, you help prevent pitfalls, promote process precision, and ensure compliance. Your diligent documentation decision directs safe food handling, delivering dependable, detailed, and disciplined record-keeping every step of the way.

How Can Small Businesses Effectively Implement HACCP?

As a small business owner, you can effectively implement food safety through a simple, tailored HACCP plan. Start by identifying hazards, then establish critical control points and monitoring procedures. Train your staff regularly, keep detailed documentation, and review your plan periodically. Using clear, manageable steps helps guarantee compliance without overwhelming your team, ultimately safeguarding your customers and your reputation. Consistency and proactive management are key to success.

What Training Is Required for Staff Regarding HACCP Procedures?

Think of employee training like planting seeds for a healthy harvest. You need to provide your staff with thorough HACCP procedures training to ensure they understand critical control points, sanitation, and safety practices. This helps them meet compliance standards and act confidently in their roles. Regular refresher courses, practical demonstrations, and clear documentation keep everyone aligned, ensuring your business maintains food safety and adheres to regulatory requirements.

Conclusion

Now that you know the essential steps to create a HACCP plan, the real challenge begins. Will your plan catch every hazard before it reaches your customers? The stakes are high, and precision is key. One overlooked risk could change everything. Are you ready to implement your plan with confidence? The safety of your food and the trust of your customers depend on it. The next move is yours—are you prepared to take it?